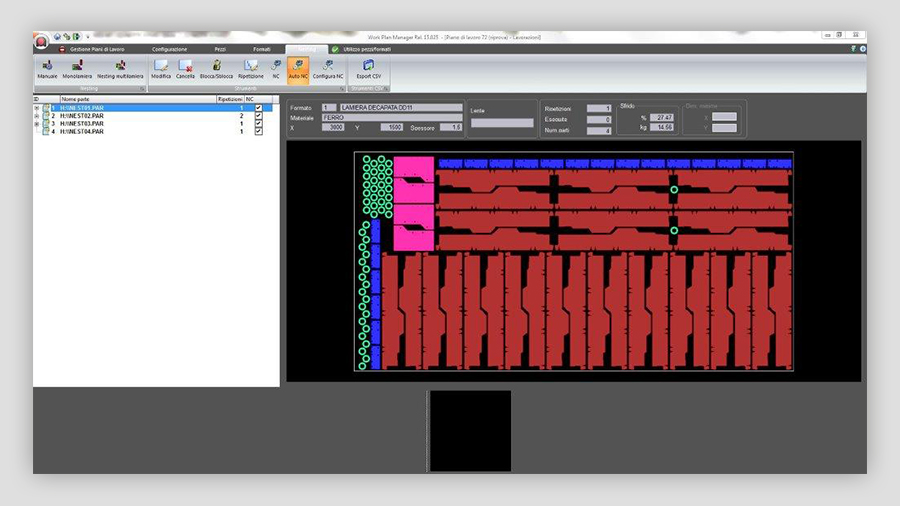

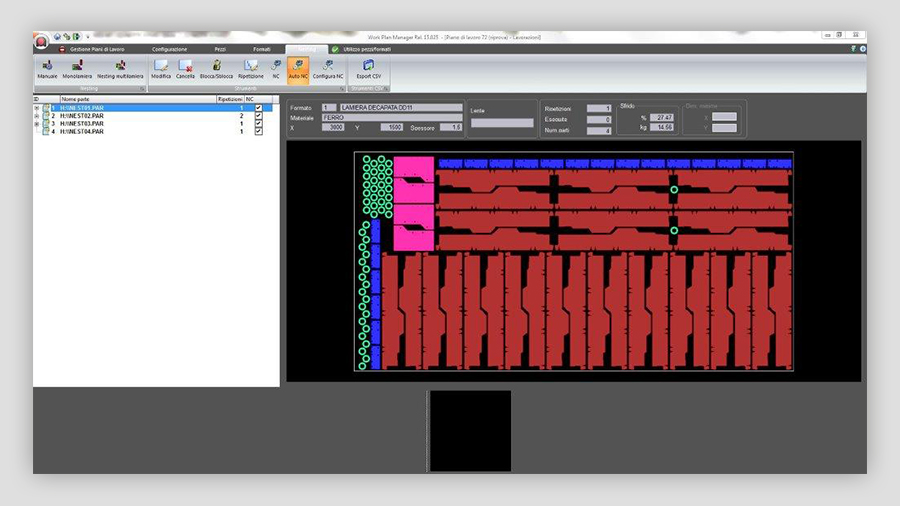

Customised CAM/CAD design

With 2D and 3D software we simulate the production of a piece and display the sequence of the phases. In this way we optimize manufacturing assuring productions without waste and on time scheduling of every order.

We support the customer from the preliminary design stage. We carry out feasibility study and 3D customised design checking all components to be assembled and evaluating possible waste. On customer’s request we design single and assembled pieces as well as full structures.

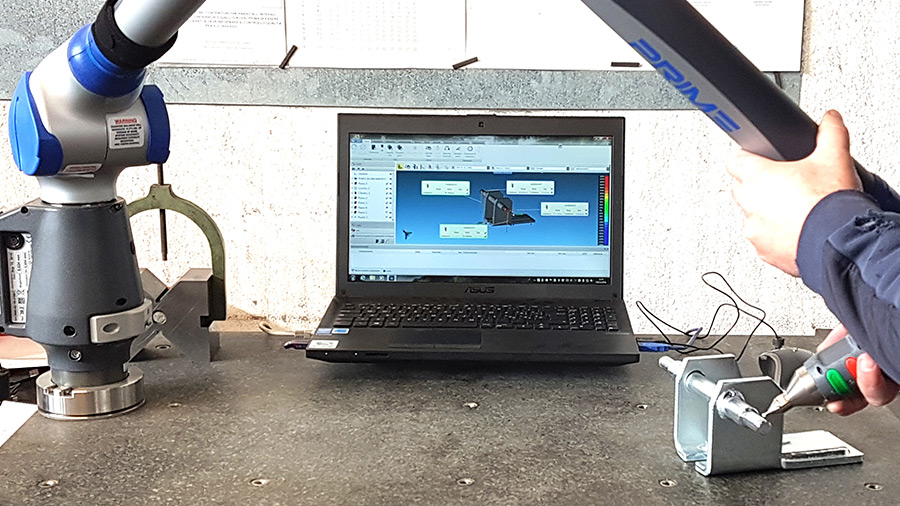

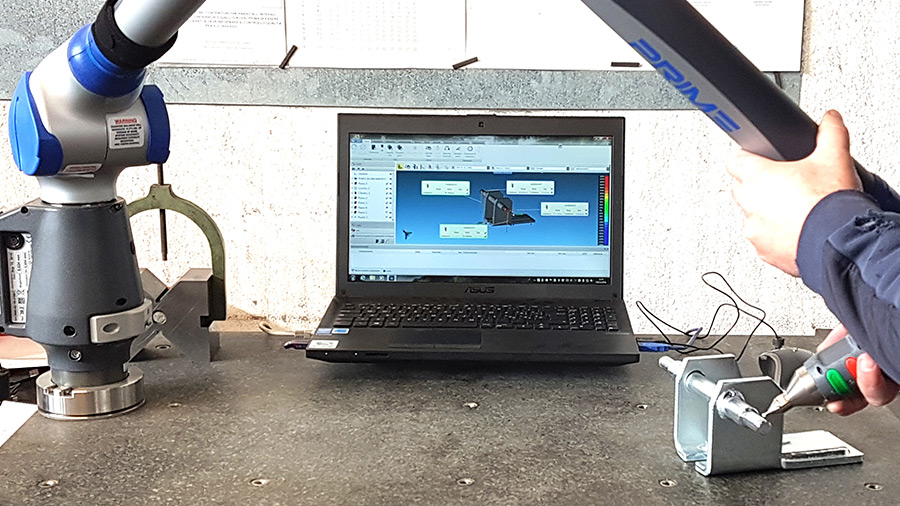

3D measuring arm

The quality control is carried out with advanced tools: our brand new measuring arm can simplify even the most difficult measurements with the highest reliability and performance.

The most recent investment by Righetti is this revolutionary portable coordinate-measuring machine (CMM). It is made up of measuring arms, laser trackers, 3D laser scanners and 3D imagers. It allows contact measurements and checks on prototypes and production samples.

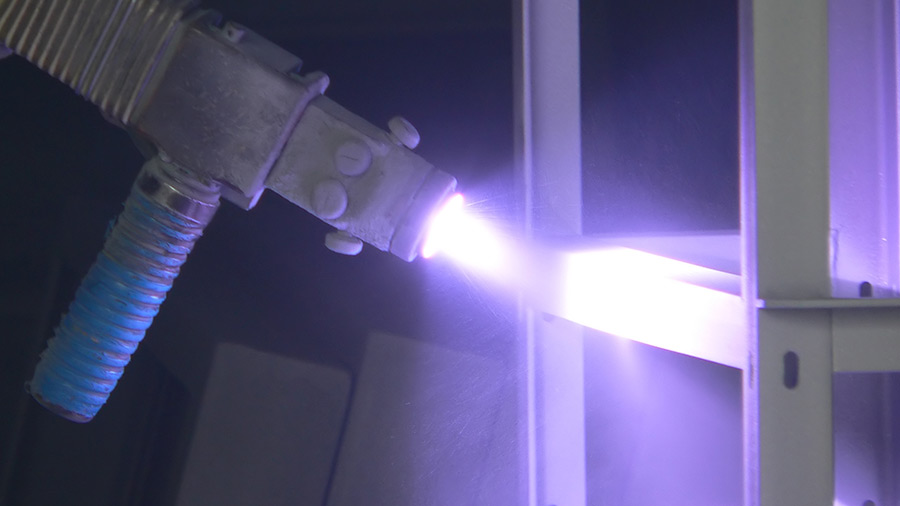

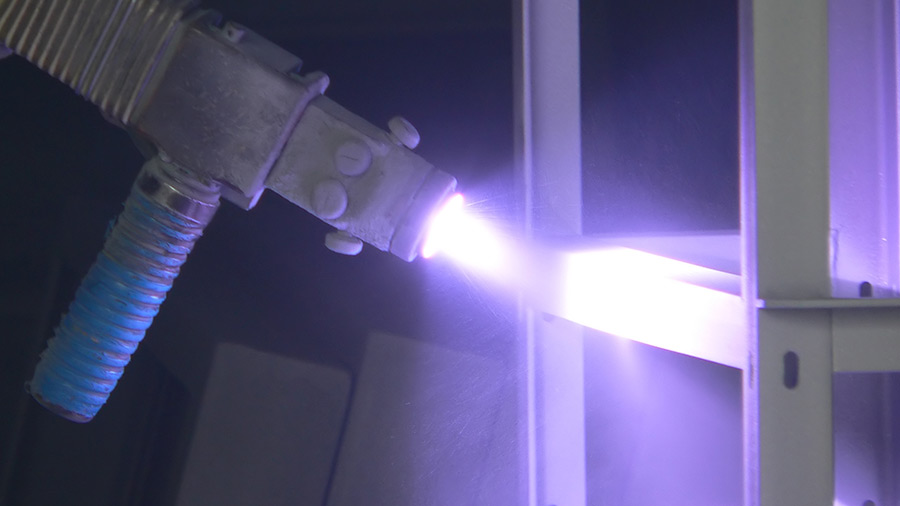

Surface treatments

The manufactured metal products can be finished with many surface treatments. Galvanic treatments, aesthetic treatments and industrial painting.

Thanks to our more than decennial partnerships with our suppliers we can guarantee excellent results to our customers. Our high qualification and the short distance between Righetti and its partners represent an additional benefit that our customers can take advantage of.

Components Assembly

In Righetti’s assembly department, single or semi-finished products and any additional component supplied by the customer are assembled to manufacture the product. Before packaging and shipping the goods, an accurate check is carried out.

Besides carrying out all production processes and finishings on a product, we can assemble the finished piece with the components supplied by the customer, with our advanced technology. Finally we proceed with packaging the goods for the final shipment to customers.